WE ARE COMPLETE LIGHTING SYSTEM MANUFACTURERS

UFO's design and manufacturing capabilities allow us to develop lighting for many sectors. If you have an idea for a lighting project and need help to bring it to life, get in touch with us today and let our experts guide you toward the light!

-

Fabrication

We can fabricate and assemble many items - from small luminaire fittings to large decorative ceiling fixtures. Our fabrication capabilities are not limited to lighting components though

We can make parts from small simple brackets to machine frames. Working with sheet and bar metals, tubes, boards, laminates and plastics to create your finished goods ready for packaging and sale. Our assembly operators are used to working with small components and we have handling equipment to deal with large items up to several metres across. -

Machining

Having spent many years serving the needs of UFO by providing custom one-off and small batch production runs, our manual machining department is used to providing quick turnaround on milled, drilled and tapped quality components in a number of engineering materials.

We can produce jigs, fixtures and special purpose machines. These can speed up production and improve repeat accuracy. Linking this to our fabrication and assembly shop will make most things possible and finishing in our paint / powder coating shop can enhance the appearance of your product. -

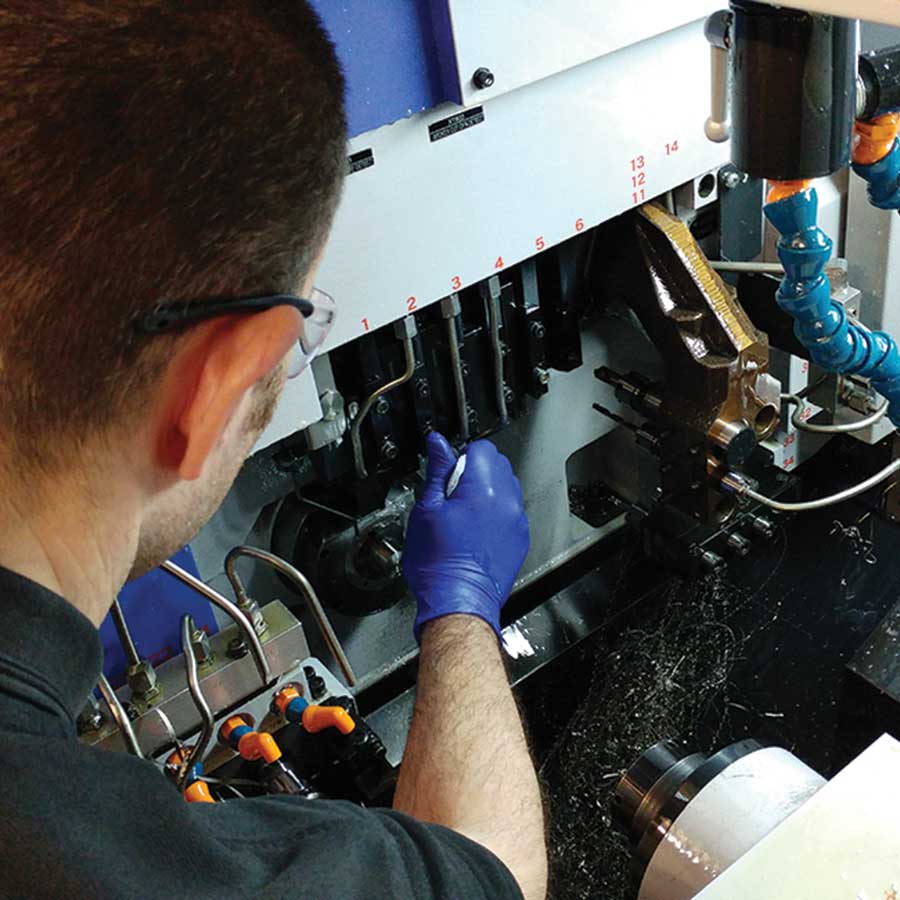

CNC Operations

On our Swiss type CNC automatics we can manufacture straight turned components or more intricate geometrical shapes by utilising driven tooling integral to the lathe.

Due to the nature of these machines they can rapidly turn, mill, drill, tap and bore a component from both sides, negating the use of a second operation machining or set up.

This results in short lead times and keeps part costs down while delivering repeatable accuracy measured in micro metres rather than millimetres over the whole batch run. -

Finishing

We can offer powder coating for a wide variety of components in a variety of shapes and sizes. Our trained finishing personnel and modern spray booths ensure a first class finish every time.

We have an electrostatic corona charge system for powder coating which can give a finished thickness of 30μm to over 70μm. We can accommodate up to a maximum component size of 800mm x 800mm x 4000mm in our large oven. Powder coating is available in all standard RAL colours and in epoxy for indoor use or polyester for outdoor use.

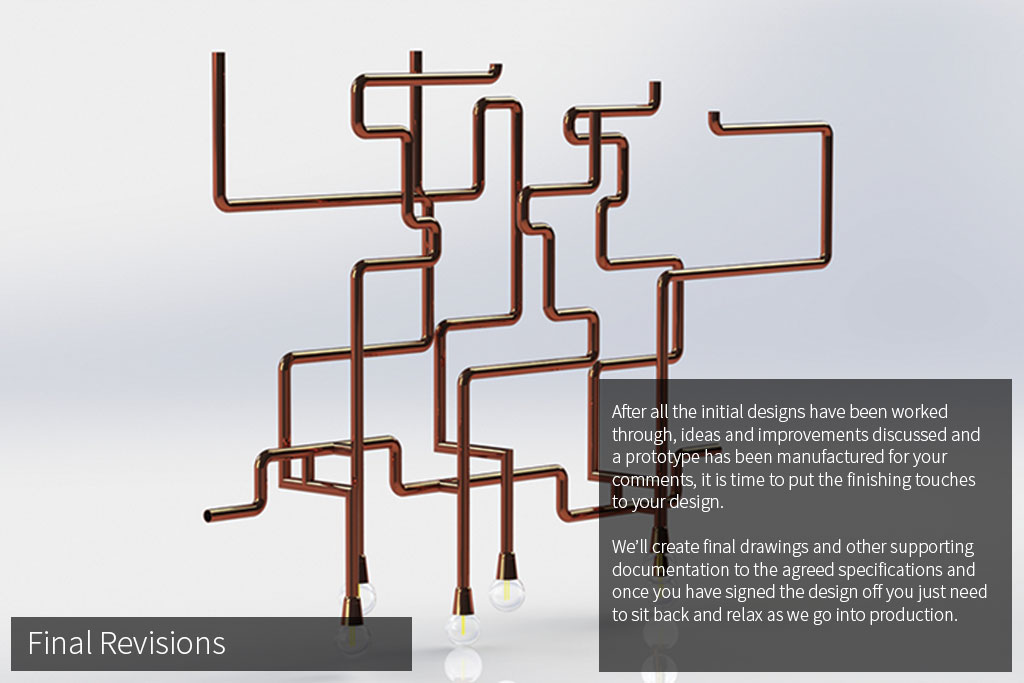

WE CAN TAKE YOUR PROJECT FROM IDEA TO FULLY INSTALLED FEATURE

Check out the panels below to see the stages of your projects journey from start to finish.